When a ship docks at a pier or docks with other ships, mooring bollards are the fixed endpoints of the cable.

The crew tightly wraps the cable around the mooring post and uses equipment such as a winch to tighten the cable, establishing a stable connection between the ship and the bollard dock or other vessels.

For example, in large ports, when container ships dock, multiple cables are tied to the mooring stakes on both sides of the ship's hull, which act as "anchor points" to firmly secure the ship to the berth.

1. In terms of ship size

2. Aspects of ship type

3.Mooring environment

4.Current, wind and wave conditions

5.Material and quality of bollard

Marine bollards are constantly exposed to harsh seawater, salt spray, and changing weather conditions. To ensure long service life and safety, material and surface protection are essential.

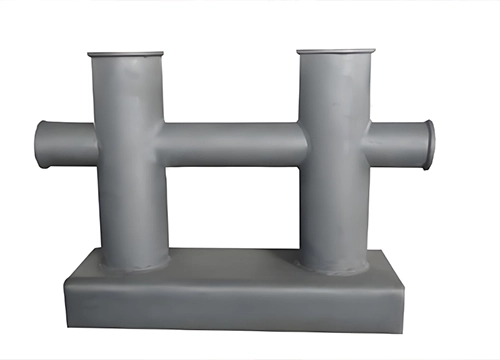

Materials: Norman boat bollards are manufactured from cast steel, ductile iron, or stainless steel, depending on the load requirement and installation environment.

Surface Treatment: Each bollard is sandblasted and coated with marine-grade epoxy paint for superior adhesion and corrosion resistance.

Corrosion Protection: For extreme marine environments, hot-dip galvanizing or special polyurethane coatings can be applied to enhance durability and reduce maintenance needs.

These measures guarantee long-term performance, even in aggressive coastal and offshore conditions.

Proper installation is critical to achieving the full strength and safety of a marine bollard.

Foundation Design: The bollard should be securely anchored to a reinforced concrete base or steel deck structure, capable of withstanding the maximum mooring load.

Mounting Options: Available as bolt-fixed or embedded types, depending on dock design and load direction.

Anchor Bolts & Reinforcement: High-strength anchor bolts and properly designed reinforcement cages are recommended to prevent movement or rotation.

Installation Notes: Ensure correct alignment, sufficient edge distance, and smooth rope operation around the bollard head.

Following proper installation guidelines ensures safety, reliability, and long-term stability of the mooring system.

When you’re dealing with heavy-duty marine operations, every link in the chain needs to be rock-solid—and that’s where high-quality marine bollards come into play. First off, these bollards provide a secure anchor point for vessels moored at docks, quays or offshore platforms. With wind, waves, tidal shifts and currents all pushing and pulling the vessel, a dedicated marine bollard ensures the ship remains in place, avoiding drift or uncontrolled movement.

Beyond simply holding a vessel in position, marine bollards offer load-distribution and structural protection. Rather than mooring lines chafing against ad hoc fixtures or being tied to unsuitable anchors, these bollards are designed to take the load safely and direct it into the dock or structure in a controlled way. That reduces stress concentrations, protects hulls, decks and quays, and contributes to operational longevity.

Durability matters. Marine environments are harsh—salt water, spray, fluctuating temperatures, heavy use. The right bollard is constructed from cast steel, ductile iron or corrosion-resistant composites, meaning it can resist wear, shock and environmental degradation for years.

Operationally, marine bollards bring versatility and adaptability to the table. They can be engineered for different vessel types—from small boats to large cargo ships—designed to cope with varying mooring loads and environmental conditions. Need quick release or high-capacity? The right bollard can be tailored accordingly.

Finally, from a safety standpoint, a well-installed marine bollard supports efficient and streamlined operations. With reliable mooring fixtures in place, loading/unloading can go ahead without hesitation, and the risk of unexpected vessel movement or rope snap-backs is significantly reduced. That means fewer delays, lower risk of accidents and a stronger reputation for safety.