Selecting the right deck machinery on board ship ensures your vessel’s safety, efficiency, and long-term reliability. When choosing, consider the following key factors:

Different vessels require different equipment.

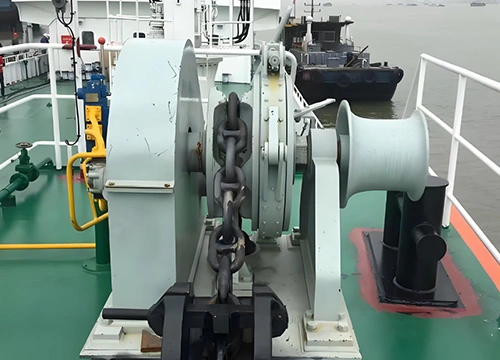

Cargo ships: focus on mooring winches and cranes.

Offshore vessels: require heavy-duty towing and anchor handling systems.

Fishing boats: often use compact hydraulic winches.

Identify your vessel type and daily operation needs before selecting the different types of deck machinery on board.

Choose machinery that matches your required working load and operation speed.

Check the line pull or lifting capacity.

Select the right power source — electric, hydraulic, or diesel-driven — depending on your ship’s power system and environment.

Marine environments are harsh. Look for:

High-strength steel or stainless steel

Corrosion-resistant coatings

Waterproof and sealed components

These features extend service life and reduce maintenance costs.

Always select products certified by major classification societies such as ABS, DNV, LR, or CCS.

Certified machinery guarantees safety and easier approval during vessel inspection.

Modern deck machinery can be equipped with:

Remote or PLC control systems

Load monitoring and safety alarms

Emergency stop functions

These features enhance operational precision and crew safety.

Choose a supplier that provides:

Spare parts availability

Technical manuals and training

Remote or on-site service

Reliable after-sales support minimizes downtime and keeps your vessel operational.

If you’re unsure which model suits your needs, our technical team can assist with custom design and selection based on your vessel’s specifications and operating conditions. Contact us today to find the best deck machinery solution for your ship.